|

||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

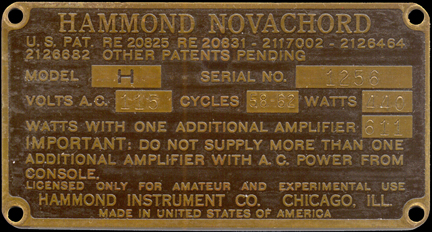

"Serial # 1256" This is approximately the 515th Novachord from a total of 1069 units made. Date of manufacture for this Novachord is roughly march 1940.

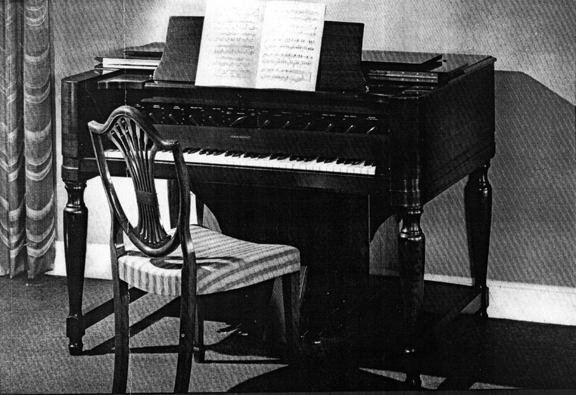

The Outer Case as it arrived at CMS. Very bad. On the other hand, most Novachord cabinets need refinishing anyway.

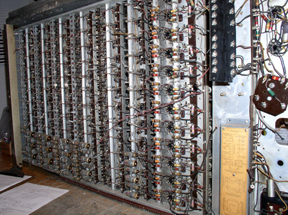

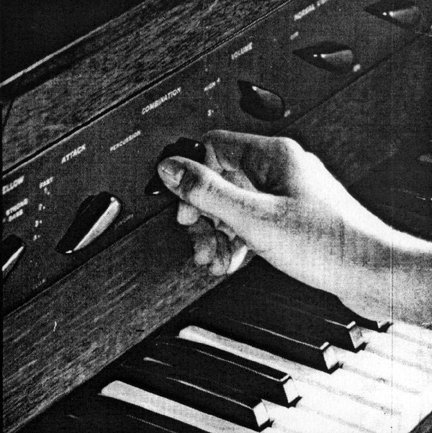

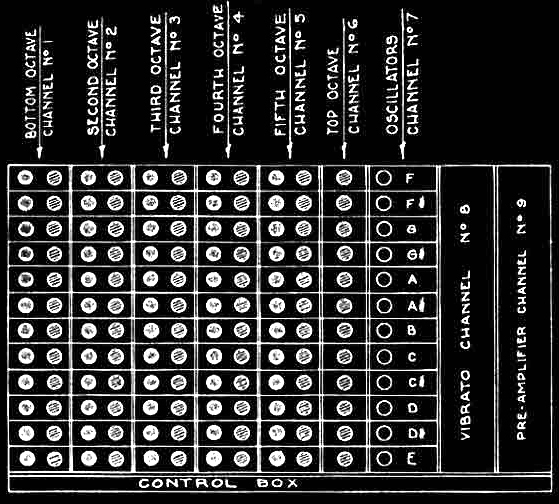

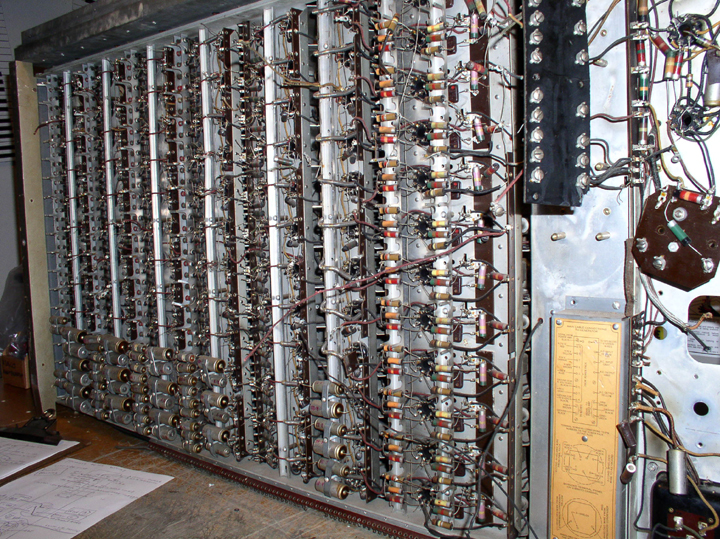

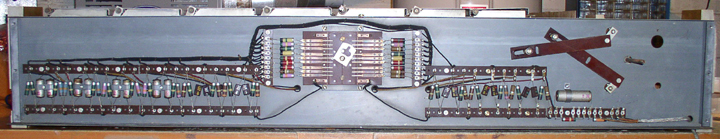

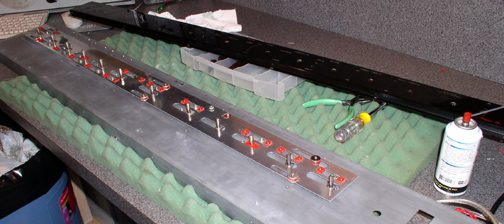

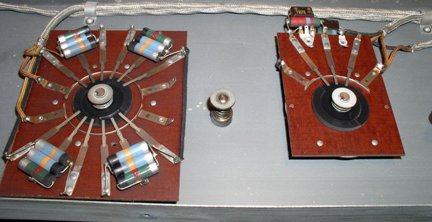

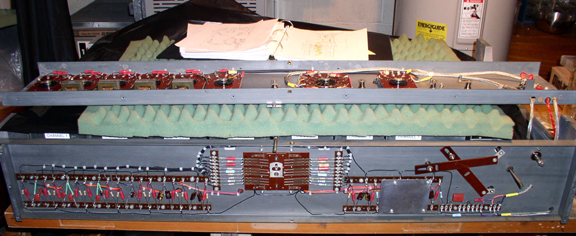

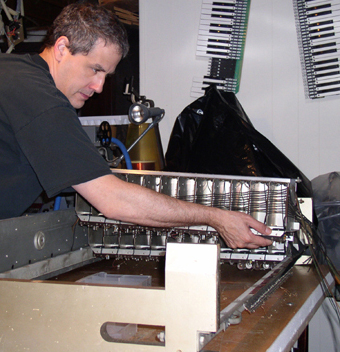

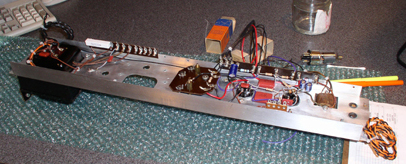

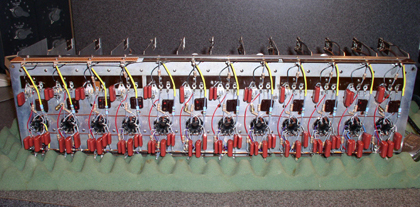

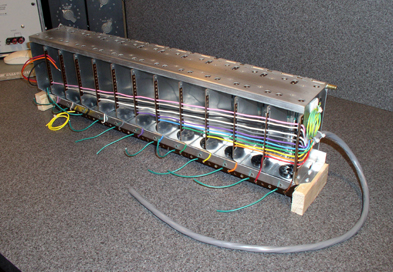

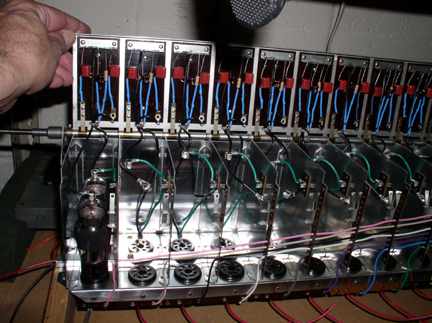

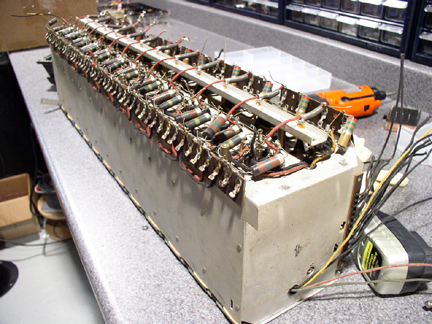

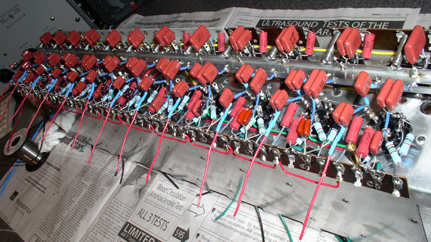

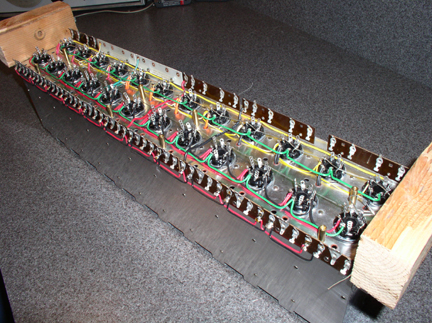

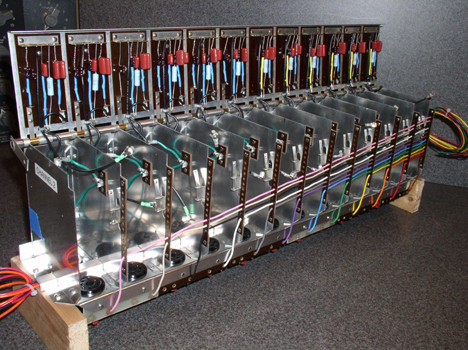

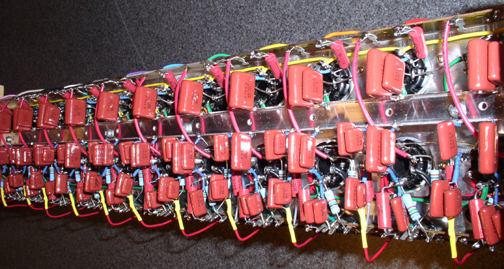

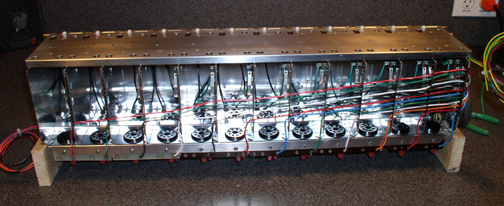

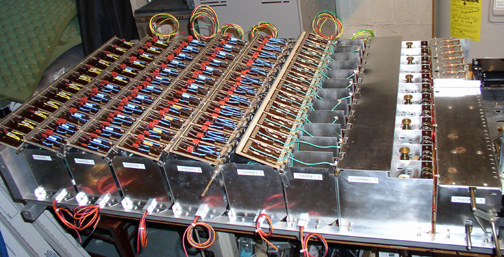

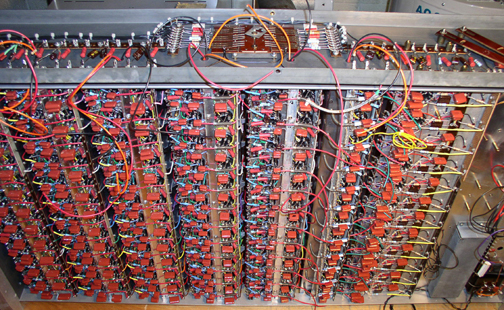

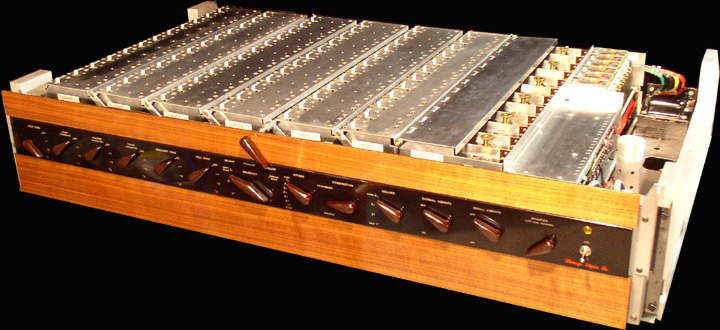

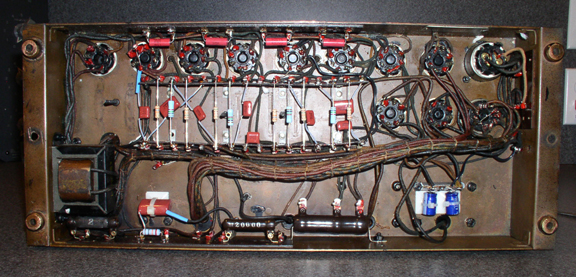

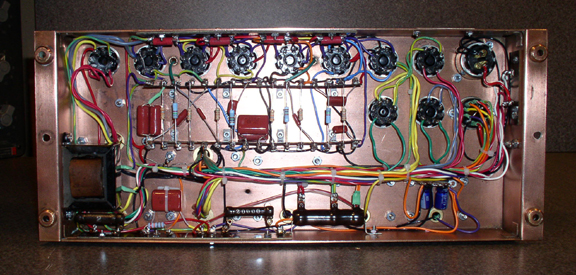

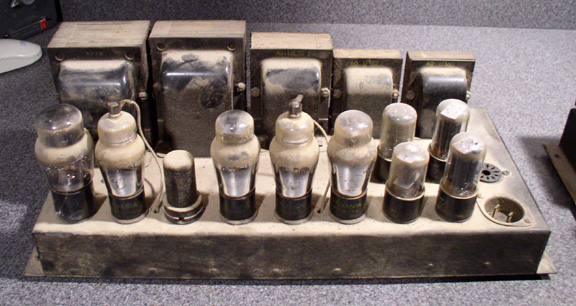

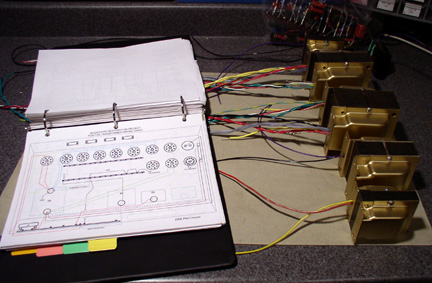

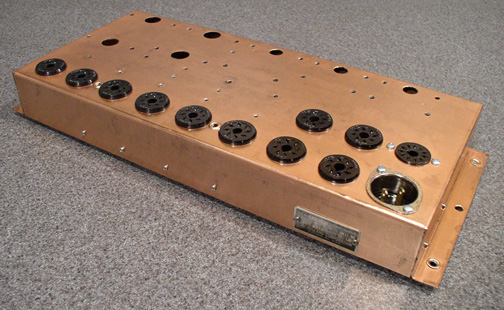

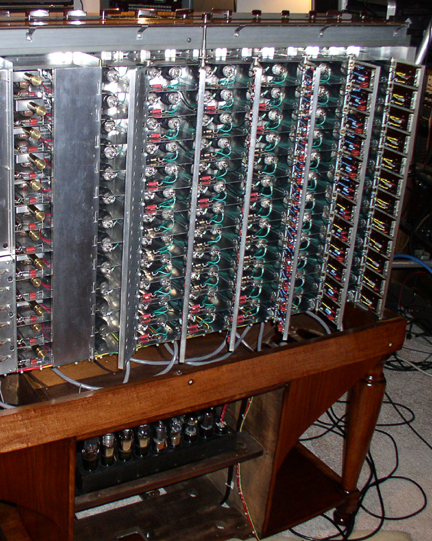

The Service Position - The Novachord has 2 major sections. The Lower Assembly and the Generator. The underside of the generator and the top of the lower assembly are shown in the above photo. The grim reality all 21st century Novachord owners must eventually face: All the custom value capacitors are unreliable, have increased in value and will continue to do so. The resistors from 1940 change value drastically depending on temperature and humidity. They all MUST be replaced. To replace just some components or even a section, would be a waste of time. This is a big job.

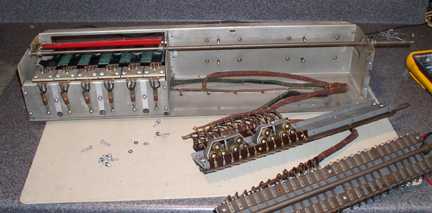

To make matters worse: A previous owner dropped this generator while it was disconnected, probably during moving, damaging many of the terminal strips riveted under the 9 channels that make up the body of the generator. To replace these strips, the channels needed to be removed. This is a massive undertaking. Warning! Don't try this at home kids!

If you subtract the wattage for the power amp that I'm not going to use, the AC power consumption is approximately 269 watts. Many people ask me - Why

a Novachord? I am a big fan of vintage horror movie,

sci-fi and spaghetti soundtracks . In the last couple of years

I have been getting into tube synths - they have this particular

sound that I find very unique. I've been using my Solovox and

Clavioline for recording, and have gotten some amazing sounds

out of them by putting them through modern digital effects. The

Novachord is a polyphonic version of these instruments, so I am

hoping to get similar results.

Some recordings out of the past The Screen Gems theme - makes a great ringtone for your cell phone Here is the incredible Pedro Moequecho and his band playing a Gershwin tune From the album "Los Anos de la Alegria". Intro by Pedro Morquecho playing "Las Hojas Muertas" Here is Pedro Moequecho and his band playing "Bahia" Here is Pedro Moequecho and his band playing"St Louis Blues" From the album "El Fabuloso Novachord". This section has a typical spooky Novachord texture that was used for underwater sequences. Jerry Goldsmith's 2nd season theme for Voyage to the Bottom of the Sea One of my personal favorites. Some very unusual sounds happening here. from Harry Lubin's music for the Outer Limits episode - "The Duplicate Man" Expanded version featuring a superbly haunting Novachord & Trautonium duet at the end. This is from the famous episode featuring Robert Culp with the "Glass Computer Hand". Collins Driggs performing the Parade of the Wooden Soldiers Collins Driggs performing When the Day is Done From the 78 RPM record.

Movie and Television listings here

|

||

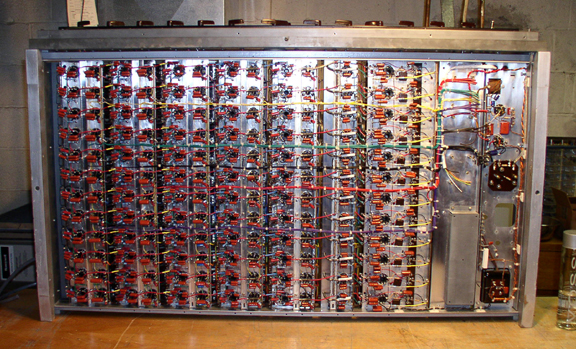

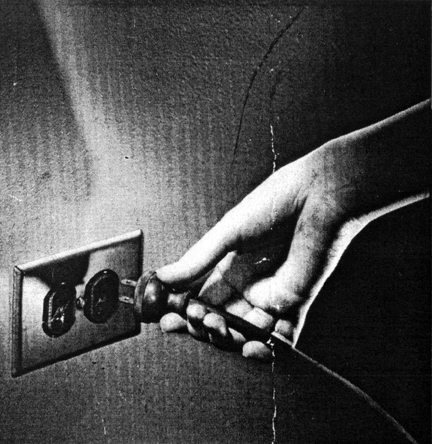

POWERING UP THE RESTORED NOVACHORD

Making the final connections

Installing the tubes

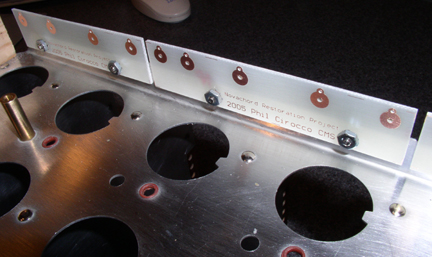

The Novachord after restoration - The Novachord was first powered up at 10:30 PM on December 1, 2005. The front lid and the music rack were still undergoing restoration at this point.

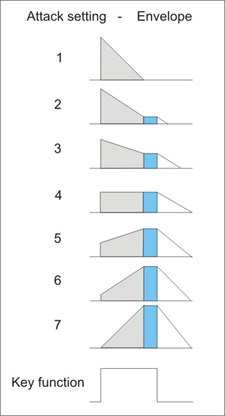

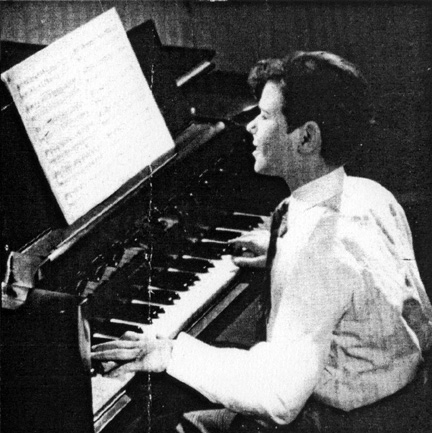

My band member Burton was over for band practice that turned into the Novachord launch. I sat there and talked with him as I installed the 146 tubes in the generator. I have to admit, I was a little scared to turn it on. I think I was stalling by checking and cleaning things. "Stop cleaning the thing and turn it on" he said. I flipped the switch and all the tubes started to glow. Check the voltages - all correct! Scope an oscillator - Working! Scope the output - Its playing notes! OMG. All these sound clips are single takes - no overdubs. Here are the first spooky sounds it made 12 / 1 / 2005 11:00 PM This may frighten small children. Novachord Improvisation #2 12 / 2 / 2005 2:30 AM This is how it sounds after being partially calibrated. Most of the notes are playing in tune and it sounds freaking amazing. Novachord Improvisation #3 12 / 3 / 2005 8:30PM This is the first part of #3. I honestly never thought the instrument would sound this damn good! Novachord improvisation #5 12 / 6 / 2005 This excerpt from #5 illustrates the range of the attack control - I know, I am an echo freak. Novachord improvisation #9 12 / 11 / 2005 This is the first part of #9. This is the Nova through the Bode 6552 frequency shifter. This is a Hammond Solovox ala Cirocco all sound files & compositions ©2005-2007 Phil Cirocco

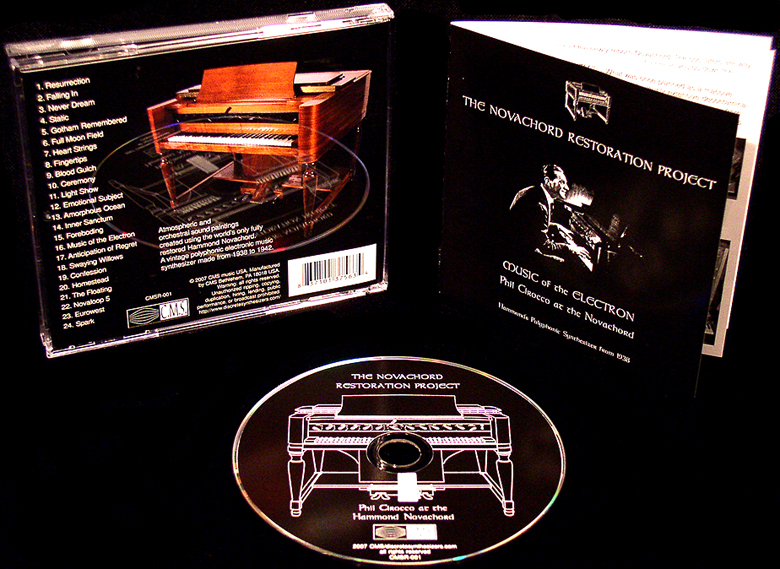

If you would like to own the better sounding, full versions of these compositions, a full length CD is now available.

The CD is now available at "CD Baby" for a special reduced price!

News Flash - The sample CD has been cancelled! This Novachord has been sampled and is available through Sonic Couture here

Email Project Manager / Novachordist Phil Cirocco here

The restored Novachord complete with the lid and music rack.

Conclusions: 1. - It's a synthesizer - Based on the old recordings I have heard, I was expecting a cross between an organ and a synthesizer. As you can hear from the sound files - It's a synthesizer! 2. - The direct output sounds great! - The balanced XLR output I installed in the preamp section drastically improved the sound of the instrument. Thanks to Mike Dal Sasso for advice on this. I am sure the speakers and enclosure really did give it a piano like quality, but I suspect the lack of high frequency response (tweeters) impeded the sound of the instrument. Probably the major reason why the instrument never caught on was the lack of any other audio equipment available at the time. 3. - The oscillators and dividers are very stable -There has been no perceptible pitch drift whatsoever - From stone cold to being on for 7 hours. I haven't touched the tuning adjustments since the first calibration. Considering how much the temperature changes inside, it's quite remarkable. Most of the tubes running in my Novachord seem to be original Sylvanias but there is no way to verify this. 4. - Modifications - Component values as well as circuit design were not altered or modified. Changes: 1. - The keyboard circuit parts locations - the smaller size of modern parts made this necessary. 2 - The keyboard to generator hookup scheme - The 72 springs were just completely off the wall. 3 - I did not use that awful cotton covered wire. Everything else was to factory spec. 5. - Thousands of passive components must be replaced. A warning to those who tread in my footsteps. I am not being negative here - just blunt. These are the harsh realities of Novachord restoration. This was an incredibly massive job! Don't embark on it unless you can handle it. For those of you who think you don't have to restore your Novachord, keep this in mind - The positive rail is at 300v DC. The negative rail is at -300v DC. With more than 1000 70 year old capacitors across those rails, the failure probability factor is nearly 100%. Keep a fire extinguisher on hand. 6. - A final warning: - Wait, it gets even worse. I love the instrument so much, so I hate saying this, but I feel obligated to warn people again about the toxic issue. If you have one, or you are considering buying one, please keep in mind that It might need a total decontamination. What's the reason for this contamination? I suspect that over the years, the large PCB oil filled capacitors inside the generator, power supply and amplifier, emit vapors that condense on all the surfaces inside the instrument. When the instrument reaches operating temp, it releases copious amounts of these fumes from all the surfaces of the instrument. Nasty.

Email Project Manager / Novachordist Phil Cirocco here

|

||

Other Resources: The Novachord Sightings page is here Movie and TV listings

The History of Electronic Music - a 1936 Perspective! - by Benjamin Miessner

Links: http://www.organhouse.com/hammond_novachord.htm http://www.oldtech.com/synth/HammondNovaC1.html http://www.synthmuseum.com/hammond/hamnovachord01.html http://theatreorgans.com/hammond/novachord/ http://www.dairiki.org/HammondWiki/HammondNovachord

|

||

|

|||||||||||||||||||||

|

|||||||||||||||||||||